With those posts i will show how to use RSLogix 5000 and Emulate 5000 to simulate a simple program.

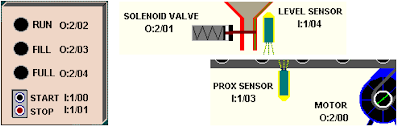

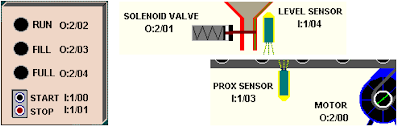

Outputs:

- Motor contactor (contactor O:2/0) moves the conveyor

- Solenoid valve (contactor O:2/1) to fill the boxes

- Run pilot lamp (O:2/2) activated when the machine is running

- Fill pilot lamp (O:2/3) activated when the machine is filling

- Full pilot lamp (O:2/4) activated when the box on conveyor is full

Inputs:

- Start Push button (I:0/0)

- Stop Push Button (I:0/1)

- Prox Sensor (I:0/2) the box is in position on his right falling edge

- Level Sensor (I:0/3) the box is full when the sensor is ON

- Three-state Selector:

I:0/4 for Continous mode

I:0/5 for Manual Restart (after a box is full, this will bring the box out of level sensor and bring a new box in position)

I:0/6 for Filling bypass

You can find the various steps here:

- Process analysis: http://mestaa.blogspot.com/2011/04/plc-training-exercise-2-with-rslogix.html

- Input mapping: http://mestaa.blogspot.com/2011/04/plc-training-exercise-2-with-rslogix.html

- Writing and manage a sequence: http://mestaa.blogspot.com/2011/05/cycles.html

- Outputs Mapping:

- Simulating the process to debug the program: http://mestaa.blogspot.com/2011/05/bsimulation-in-test-driven-development.html

- Exercise file for RSLogix 5000: http://www.megaupload.com/?d=9GXL96L7

I will also cover all the steps that are needed to realize a program with ladder logic and a simple sequence, to give a sample on how you could base your automation projects.

The text of the exercise is available here: http://www.megaupload.com/?d=PIWQA7AS

Realize the automation of the following Filling system:

Outputs:

- Motor contactor (contactor O:2/0) moves the conveyor

- Solenoid valve (contactor O:2/1) to fill the boxes

- Run pilot lamp (O:2/2) activated when the machine is running

- Fill pilot lamp (O:2/3) activated when the machine is filling

- Full pilot lamp (O:2/4) activated when the box on conveyor is full

Inputs:

- Start Push button (I:0/0)

- Stop Push Button (I:0/1)

- Prox Sensor (I:0/2) the box is in position on his right falling edge

- Level Sensor (I:0/3) the box is full when the sensor is ON

- Three-state Selector:

I:0/4 for Continous mode

I:0/5 for Manual Restart (after a box is full, this will bring the box out of level sensor and bring a new box in position)

I:0/6 for Filling bypass

You can find the various steps here:

- Process analysis: http://mestaa.blogspot.com/2011/04/plc-training-exercise-2-with-rslogix.html

- Input mapping: http://mestaa.blogspot.com/2011/04/plc-training-exercise-2-with-rslogix.html

- Writing and manage a sequence: http://mestaa.blogspot.com/2011/05/cycles.html

- Outputs Mapping:

- Simulating the process to debug the program: http://mestaa.blogspot.com/2011/05/bsimulation-in-test-driven-development.html

- Exercise file for RSLogix 5000: http://www.megaupload.com/?d=9GXL96L7